Let intelligent forging become the right-hand man in the field of metal plastic forming

Based on the fields of household appliances, electronics and aerospace, Juhe Smart Forging focuses on the same service forging of lightweight aluminum alloy forging of automobiles, structural parts of new energy lithium batteries, metal plates of hydrogen fuel cells and plastic forming of metal precision functional structural parts in the field of energy storage.

Intelligent

Servo

Forging

Stamping

JIANGSU UNION SERVO TECHNOLOGY Co., Ltd.

ZD-JUST specializes in the household appliances, electronics, and aerospace sectors while strategically focusing on lightweight aluminum alloy forging for the automotive industry, structural components for lithium-ion battery cells in new energy applications, metal bipolar plates for hydrogen fuel cells, and servo forging of precision functional metal components in the energy storage sector. The company is dedicated to helping customers save time, labor, materials, and costs, ensuring that their plastic forming processes achieve high efficiency, superior quality,

precision, and energy savings. Additionally, the company provides diagnostic services to evaluate existing production methods, offers lean manufacturing proposals, and retrofits traditional equipment with advanced servo technology, maximizing value and delivering exceptional

service to its clients.

Labor saving, time saving, material saving and cost saving

Tailored, beyond imports

View MoreJUST Smart Forging Helps the Development of Various Industries

Based on the fields of home appliances, electronics and aerospace, Juhe Smart Forging focuses on the servo forging of lightweight aluminum alloy forging of automobiles, new energy lithium battery core structural parts, hydrogen fuel cell metal plates and metal precision functional structural parts in the field of energy storage.

Aerospace

Home appliances

Car

Forging

Fins

Motor

JUST Smart Forging-Enterprise Advantage

Looking forward to new and old customers to provide us with new platforms and opportunities, we will further to meet more new challenges, anytime, anywhere to accept your inspection of us! Let's go hand in hand to make our respective contributions to the realization of intelligent forging empowerment.

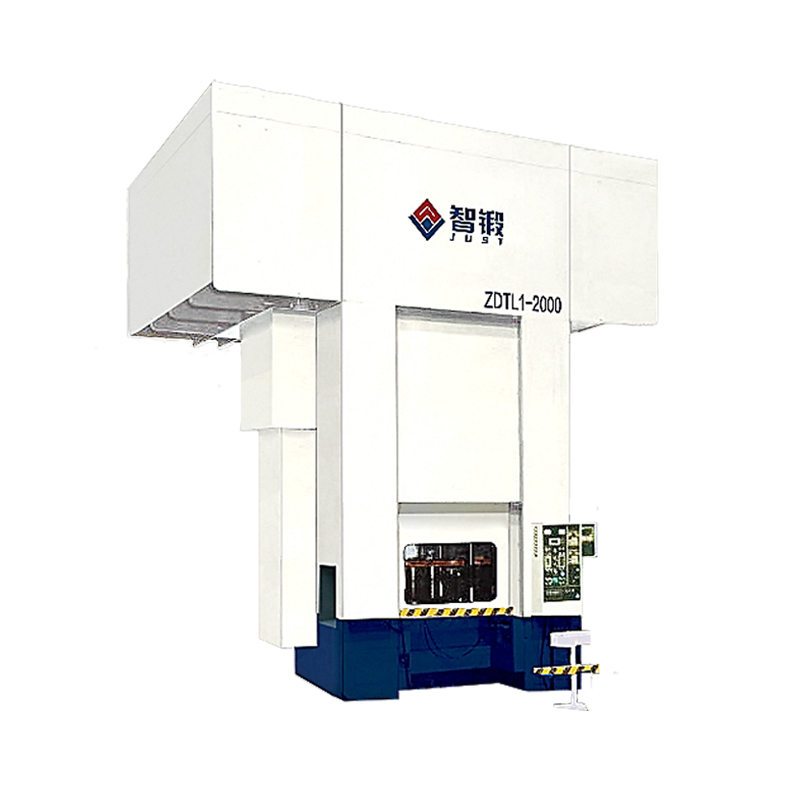

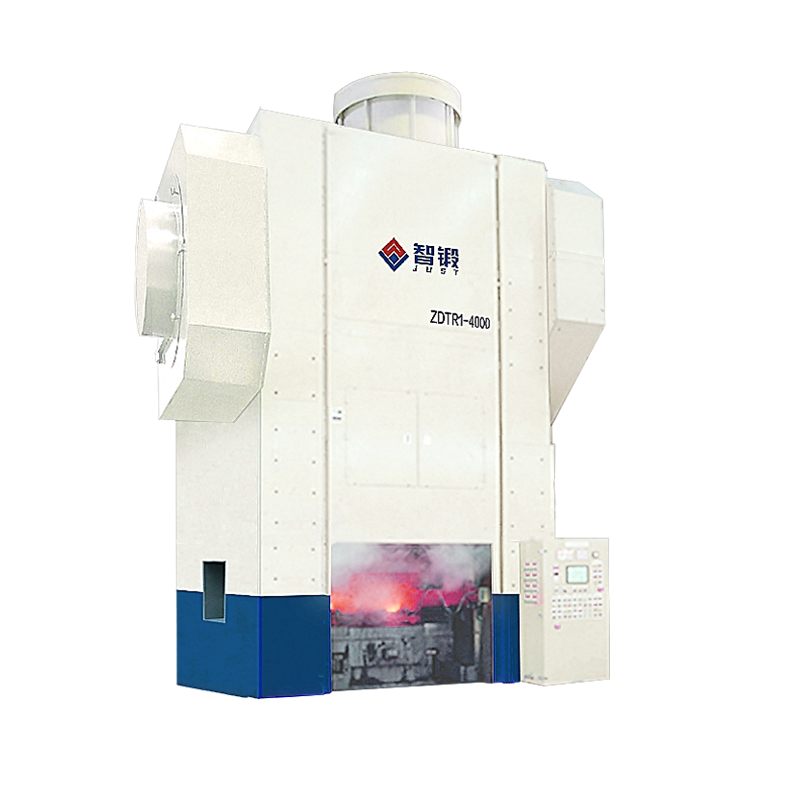

This technical service is to carry out servo transformation and upgrade on ordinary mechanical presses (that is, "transform ordinary mechanical presses into servo presses"). This allows stamping processing factories to obtain advanced servo press technical services at a relatively small cost. Currently, the servo motor torque ranges from 2500 Nm to 35000 Nm per unit. It can realize the transformation of presses from 80 tons to 3000 tons, covering most of the models in the stamping and forging markets.

Product Features

The transmission mechanism and the servo motor are connected by splines, which is simple and convenient to install, does not need to pull the press out as a whole for transformation, and the construction period is short.

The permanent magnet synchronous servo motor with low speed and high torque air cooling is adopted, which has strong overload capacity, high control accuracy and strong process adaptability.

High-power servo drive, and servo motor matching is good, press do large function, available servo mode to do deep drawing processing.

Presses above 1000T are usually driven by 2 or 4 servo motors. Smart forging's multi-motor servo synchronization technology can realize this transformation.

After the transformation, the control system can realize data acquisition, remote maintenance, and reserve MES interface.

Configure energy management system, energy saving and environmental protection.

The company has the independent design and manufacturing capabilities of forging, stamping and pressing equipment and peripheral automation devices, and provides reasonable stamping automation solutions and turnkey projects from molding process analysis, mold design, processing and debugging, presses, manipulators and other peripheral devices, as well as control systems, according to customer needs. You only need to provide the drawings of the production parts, and we will do the molding process analysis and CAE analysis of the parts, and design a professional, practical, and cost-effective stamping and forging production line plan for you.