Inverter/Servo Knuckle precision press

Classification:

Key words:

Inverter/Servo Knuckle precision press

Product Details

Standard configuration

● Inverter motor/Servo synchronous motor

● Wet clutch device

● Oil pressure overload protection

● Automatic oil circulation lubricator

● Slider and upper die balancing device

● Automatic lubricator

● Photoelectric safety device

● Double circuit safety protection

● Overstroke inspecting device

● Reserved automatic electrical interface

● Touch screen panel

● Production counter

● Air injector/Air outlet 3/8B

● Detection device for material misdelivery

● Power socket (five-hole, AC220V)

● Mould area light

Optional configuration

● Anti vabrication pad

● Tonnage meter

● Quick die exchange device

● Slider upper feeding device

● Air-pressure type die cushion device

● Front/Back safety doors/fences/ladders

● Peripheral automation device

| Inverter/Servo knuckle precision press | Inverter/Servo Knuckle double point precision press for cover plate stamping | |||||||||

| Paramater / Model | Single Point | |||||||||

| ZDK1-160/ ZDSK1-160 | ZDK1-200/ ZDSK1-200 | ZDK1-300/ ZDSK1-300 | ZDK1-400/ ZDSK1-400 | ZDK2-600/ ZDSK2-600 | ZDK2-800/ ZDSK2-800 | ZDK2-1000/ ZDSK2-1000 | ZDK2-1250/ ZDSK2-1250 | |||

| 1 | Nominal force | KN | 1600 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12500 |

| 2 | Nominal force stroke | mm | 6 | 6 | 7 | 7 | 3 | 3 | 4 | 4 |

| 3 | Slide stroke length | mm | 180 | 200 | 200 | 250 | 80 | 80 | 80 | 80 |

| 4 | Unloaded continuous stroke number | SPM | 40~80/ 1~80 | 35~70/ 1~70 | 35~70/ 1~70 | 30~60/ 1~60 | 55~110/ 1~110 | 55~110/ 1~110 | 40~80/ 1~80 | 40~80/ 1~80 |

| 5 | Die height | mm | 400 | 450 | 450 | 500 | 500 | 500 | 550 | 550 |

| 6 | Slide adjustment | mm | 90 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 7 | Slide area(LR*FB) | mm | 700x600 | 750x700 | 800x750 | 1000x750 | 2300x1000 | 2300x1000 | 2500x1200 | 2500x1200 |

| 8 | Bolster area(LR*FB) | mm | 700x700 | 750x750 | 800x800 | 1000x800 | 2300x1000 | 2300x1000 | 2500x1200 | 2500x1200 |

| 9 | Side opening(FB*H) | mm | 500x400 | 500x400 | 600x400 | 700x450 | 700x500 | 700x500 | 800x550 | 800x550 |

| 10 | Maximum upper die weight | Kg | 600 | 700 | 800 | 1000 | 2500 | 2500 | 3500 | 3500 |

| 11 | Main motor power (Inverter ZDK1) | Kw | 19 | 22 | 30 | 37 | 55 | 75 | 90 | 110 |

| 12 | Maximum torque of servo motor (Servo ZDSK1) | Nm | 6000 | 7500 | 12000 | 16000 | 9000 | 12000 | 2*9000 | 2*12000 |

| nverter/Servo knuckle precision press | |||||||||||

| Paramater / Model | double points | ||||||||||

| ZDK2-200/ ZDSK2-200 | ZDK2-300/ ZDSK2-300 | ZDK2-400/ ZDSK2-400 | ZDK2-600/ ZDSK2-600 | ZDK2-800/ ZDSK2-800 | ZDK2-1000/ ZDSK2-1000 | ZDK2-1250/ ZDSK2-1250 | ZDK2-1600/ ZDSK2-1600 | ZDK2-2000/ ZDSK2-2000 | |||

| 1 | Nominal force | KN | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12500 | 16000 | 20000 |

| 2 | Nominal force stroke | mm | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 10 | 10 |

| 3 | Slide stroke length | mm | 200 | 200 | 250 | 280 | 300 | 350 | 350 | 400 | 400 |

| 4 | Unloaded continuous stroke number | SPM | 35~70/ 1~70 | 35~70/ 1~70 | 30~60/ 1~60 | 30~55/ 1~55 | 25~50/ 1~50 | 25~45/ 1~45 | 25~45/ 1~45 | 20~35/ 1~35 | 20~35/ 1~35 |

| 5 | Die height | mm | 500 | 550 | 600 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| 6 | Slide adjustment | mm | 70 | 70 | 100 | 100 | 100 | 200 | 200 | 300 | 300 |

| 7 | Slide area (LR*FB) | mm | 1500x800 | 1800x900 | 2200x1000 | 2500x1100 | 2800x1200 | 4000x1400 | 4500x1500 | 5000x1600 | 5500x1700 |

| 8 | Bolster area (LR*FB) | mm | 1500x900 | 1800x1000 | 2200x1100 | 2500x1200 | 2800x1300 | 4000x1500 | 4500x1600 | 5000x1700 | 5500x1800 |

| 9 | Side opening(FB*H) | mm | 600x450 | 600x500 | 700x550 | 700x600 | 700x700 | 1500x800 | 1500x800 | 1700x1000 | 1700x1000 |

| 10 | Maximum upper die weight | Kg | 1500 | 2000 | 2500 | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 |

| 11 | 主Main motor power(Inverter ZDK2) | Kw | 22 | 30 | 37 | 55 | 75 | 132 | 160 | 220 | 280 |

| 12 | Maximum torque of servo motor (Servo ZDSK2) | Nm | 7500 | 12000 | 16000 | 2*12000 | 2*16000 | 2*22000 | 2*27000 | 2*35000 | 4*22000 |

The above are standard specifications or actual performance data, which can be adjusted according to customer needs.

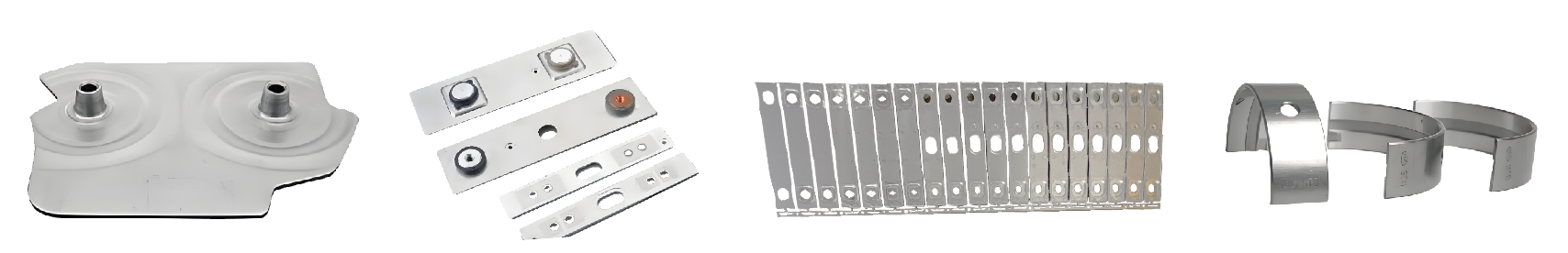

Application products

Related Products

Welcome your message consultation